This foundation has given rise to some of our most important breakthroughs. For navigation, our TrackVLA model requires only a single natural language instruction to guide a robot through complex environments—navigating obstacles, interacting with humans, and maintaining stable performance even in crowded, dynamic spaces. We debuted TrackVLA earlier this year, showing how robots can follow humans in real time without pre-mapping, even in highly cluttered or interference-heavy environments.

On the manipulation side, we launched GraspVLA, the world’s first foundational model capable of real-time closed-loop grasp generation. GraspVLA enables zero-shot grasping across rigid and deformable objects alike, under different lighting conditions and challenging backgrounds—without prior object-specific training. Built on GraspVLA and GroceryVLA, we developed a retail application scenario showcased at the World Artificial Intelligence Conference (WAIC) 2025, where Galbot performed live demonstrations of real-shelf grasping in front of global leaders. From bottles and bags to hanging merchandise and soft goods, the same model handled hundreds of different object types, making it the world’s first end-to-end retail embodied large model with such breadth of generalization.

These advances underscore why we believe Sim2Real and embodied large models represent the future of robotics: they reduce costs, accelerate iteration, and deliver robust generalization. We presented these results at the Conference on Robot Learning (CoRL) 2025, showing how scalable synthetic data and embodied foundation models can strengthen generalization across diverse environments and benefit the broader robotics community.

We see this not only in our own research and deployments, but also in how the next generation of innovators is beginning to engage with robotics. As the exclusive technical partner of the 2nd International Olympiad in Artificial Intelligence (IOAI), Galbot provided a complete simulation-to-real platform for over 300 high school students from 61 countries. For the first time, these students were able to design algorithms in simulation and then deploy them directly onto real humanoid robots in tasks that simulated real industrial environments. This hands-on experience with Galbot was transformative: it showed young innovators that their ideas could leap from code into physical machines, inspiring them to push the boundaries of what robotics can achieve.

Beyond the gold medal, what did you personally take away from seeing Galbot compete under pressure on the world stage?

What moved me most was the cohesion and execution of our team. Winning the gold medal would have been impossible without seamless collaboration and decisive execution of our technical team. The fact that we were able to adapt and innovate on such short notice—such as redesigning the robot’s fingers the night before the competition—shows the strength of our team. It just reaffirmed that success in robotics, and in innovation more broadly, is not just about the technology; it is about how effectively a team can come together to tackle complex challenges. Watching Galbot perform under pressure, with only a week of preparation and an hour of onsite practice, reminded me how far we’ve come. It was a proud moment for the entire team.

How does this victory help in convincing governments, investors, and healthcare institutions to adopt autonomous robots more widely?

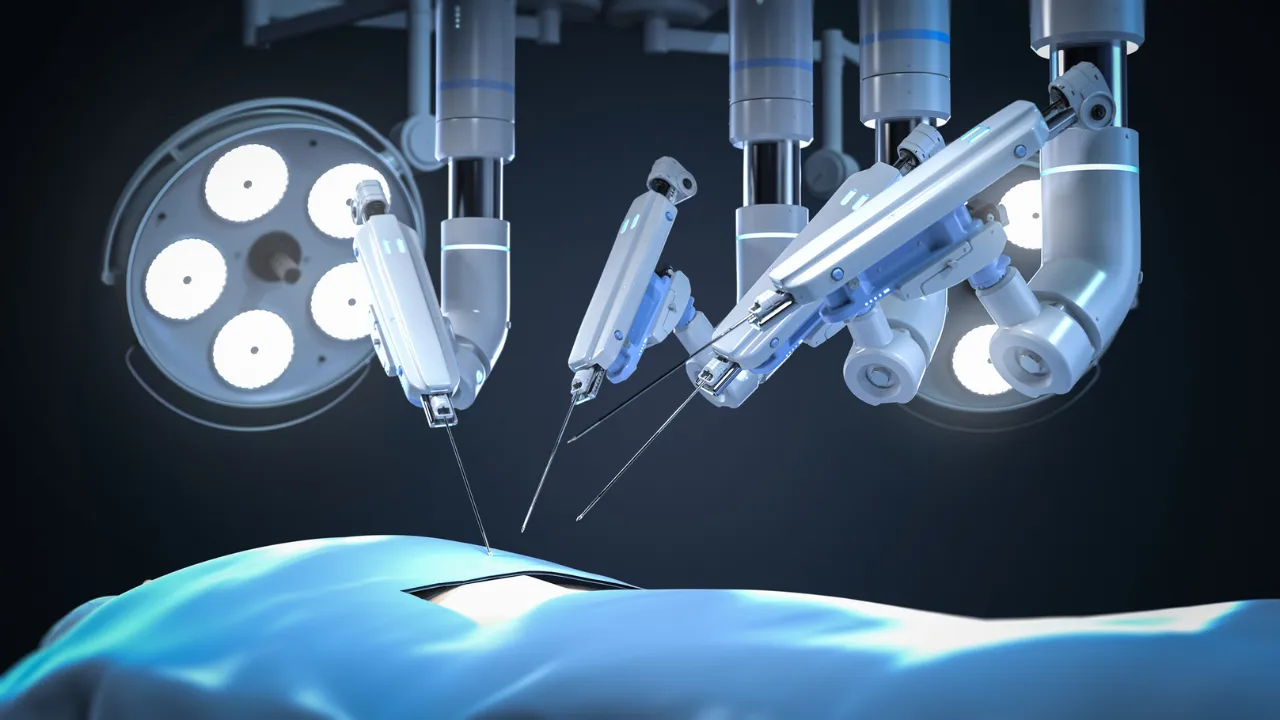

This victory validated Galbot’s technology on a global stage, and in a scenario directly relevant to healthcare. Pharmaceutical sorting is a high-stakes, safety-critical task. By winning decisively, Galbot proved that autonomous robots can be trusted in such sensitive environments. That confidence is already translating into adoption. Our robots are deployed in over 10 pharmacies in Beijing and will expand to 100+ stores in one year. Beyond pharmacies, we’ve launched the world’s first fully autonomous humanoid-powered retail store that is operated entirely by the humanoid robot Galbot G1, serving thousands of people each day. These deployments show governments, investors, and healthcare institutions that the technology is both reliable and commercially viable. The gold medal shows the world that Galbot is not a lab demo. It is a global leader ready for real-world scale.

With expansion planned to 100+ pharmacies, what safeguards are in place to ensure safety, reliability, and trust in such sensitive environments?

Safety has always been our first design principle. Each Galbot robot includes redundant sensors, algorithms, and control systems, ensuring continuous monitoring and fail-safe operation. This is complemented by extensive field validation: our robots have already been running 24/7 in pharmacies, where they’ve proven stable, reliable, and safe in long-term operation.

The wheel-based dual-arm design also provides industrial-grade stability and endurance, enabling continuous operation without compromising safety. For example, in our autonomous pharmacies powered by Galbot G1, each unit manages up to 5,000 SKUs—including fragile packaging—without human intervention. These safeguards give us and our partners confidence that Galbot can operate reliably in healthcare and retail environments, where safety and trust are paramount.

If we fast forward five years, what role do you imagine Galbot—or humanoid robots in general—will play in everyday human life?

In five years, I believe humanoid robots will become a familiar presence in industries and everyday life. They will take on tasks that are too tedious, repetitive, or dangerous for humans, and they will increasingly provide customer-facing services in urban spaces.

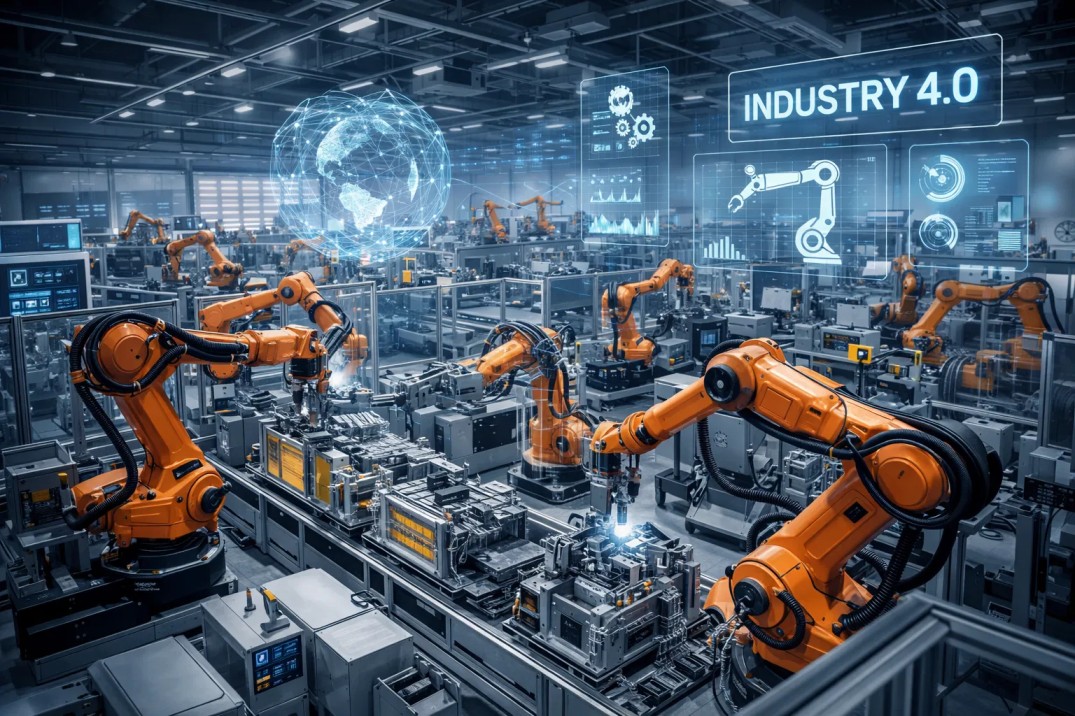

When I imagine this future, I don’t see robots confined to a single job. I see integrated ecosystems of robots working side by side, much like what we demonstrated at the World Robotics Conference (WRC) this July. On one stage, Galbot robots prepared and served coffee to visitors, while others autonomously performed industrial tote handling and material transport. Meanwhile, our quadruped robots performed city-service tasks such as trash collection. All of this ran simultaneously and without teleoperation. That demonstration was more than a showcase—it was an early prototype of how heterogeneous robotic systems can coordinate across domains to create truly intelligent environments.

This vision is already becoming reality. Our autonomous retail store pilot in Beijing presents how humanoid robots can deliver real, everyday value to citizens in retail. Each store is running by Galbot G1, offering drinks, snacks, and pharmaceuticals under both chilled and frozen conditions. Powered by our GroceryVLA and GraspVLA embodied large models, the store operates without teleoperation and adapts in real time to densely packed shelves and diverse product packaging. For citizens, it feels like a smarter, more interactive version of a convenience store. For us, it’s proof that humanoid robots can provide reliable, practical service in daily life.

The same principle applies in industrial settings, where Galbot robots are already approaching human-level efficiency in totes handling and material transport. By the end of this year, we expect deployments to scale into the thousands across industrial and commercial sectors. Taken together, these pilots show that robots will not remain confined to labs or one-off exhibitions. They will become trusted workers embedded in the infrastructure of daily life—from pharmacies and retail stores to factories and city streets. That is the trajectory we are building toward, and in five years, I expect robots like Galbot to be integral to the way our society functions.