From pilot to production: How physical AI will reshape construction job sites in 2026

29 December 2025 | Expert Insight | By editor@rbnpress.com

As labor shortages rise and demand for complex infrastructure accelerates, physical AI is moving from pilot projects to real-world deployment—reshaping productivity, safety, and competitiveness in construction.

The construction industry will experience major shifts in the coming years. With surging demand for advanced construction projects like data centers and next-generation energy infrastructure, construction firms are facing significant challenges—such as rising costs and labor shortages. This is why AI-powered automation is increasingly important in the sector, as it has the potential to drastically improve efficiency, drive down costs, and keep pace with the requirements for speed and accuracy that traditional construction methods are struggling to meet.

Despite near-term economic headwinds, construction firms need to be capable of capitalizing on a new era of construction driven by the AI revolution, the global transition to renewable energy, and other technological shifts. Physical AI will be integral to the transformation of the construction industry, as it will address urgent labor shortages, increase productivity, and improve safety. The development of physical AI is accelerating, and innovative construction firms recognize that it will be a key competitive differentiator in the years to come.

While we won’t see full autonomy in the near future, 2026 will be a pivotal year for physical AI in construction. Technology like AI models and software-defined machinery is now moving from the pilot to the deployment phase, and the industry is collecting actionable data directly from real-world job sites. This will create a positive feedback loop that enables more advanced implementations, which will in turn generate even better data. This is the foundation of physical AI in construction, and it is becoming stronger every day.

Physical AI will permanently transform the construction industry

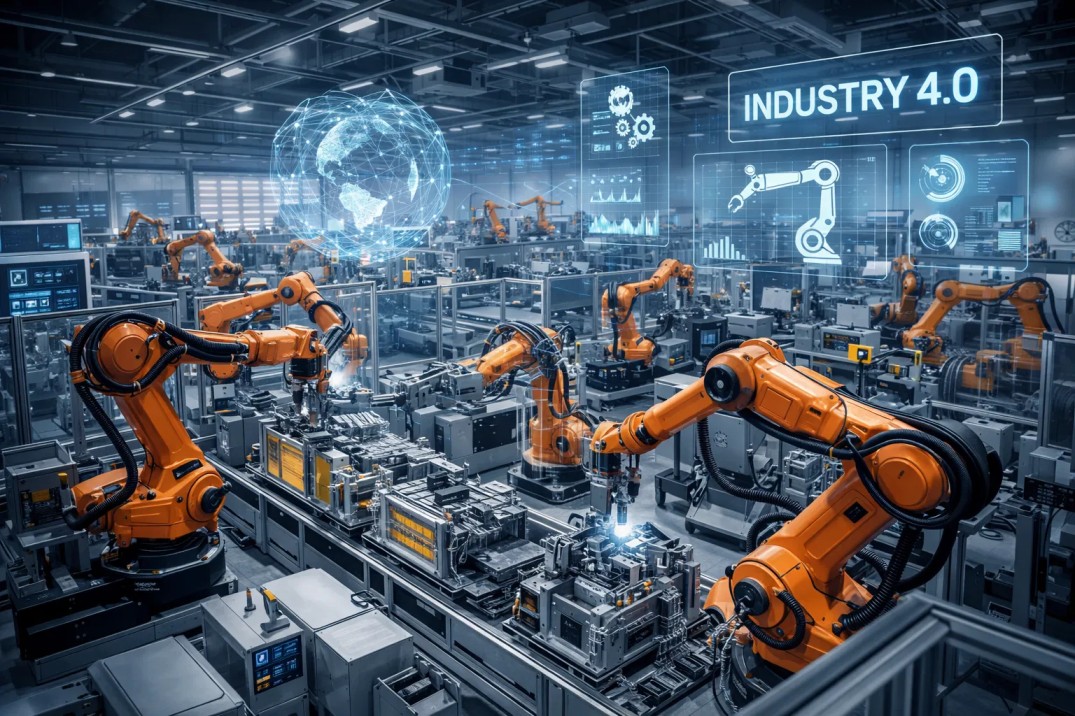

The economy has become steadily more efficient and productive over the past two decades. This is particularly true of industries like manufacturing, in which the real gross value added per worker has nearly doubled since 2000. Over the same period, this value only increased by about 10 percent for construction workers. One of the main reasons for this discrepancy is the outsize role of automation in manufacturing, which has enabled the sector to achieve productivity gains significantly higher than the rest of the economy.

There’s a reason construction is regarded as the last frontier of automation—while factories are generally structured and predictable environments, construction job sites are far more dynamic and unpredictable. Every job site is different: weather conditions are in a constant state of flux, heavy machinery is frequently in motion, and the physical environment changes dramatically over the course of a project. Paradigm-shifting technologies like machine learning and robotics have been deployed more widely in manufacturing, which has driven a productivity renaissance in the sector. But it has proven to be more difficult to deploy those technologies in construction.

The rapid evolution of physical AI can finally bring the power of automation to the construction industry. Advanced equipment like LiDAR, GNSS, and IMUs can analyze and react to shifting conditions in real time, AI models are capable of making task-level decisions, and software-defined machinery and robotics can perform increasingly precise physical tasks. Physical AI is the path to scalable automation in construction, which will drive a new era of efficiency, precision, and safety.

The accelerating progress toward physical AI in construction

One of the biggest impediments to the development of physical AI is a lack of data. Unlike generative AI applications such as large language models (LLMs), there isn’t a vast universe of preexisting online data that physical AI can draw upon. Physical AI can only be developed by collecting data from the real world—a process that requires specialized machinery operating at actual job sites. The collection of vital data such as equipment interactions with shifting terrain and weather, machine motion trajectories, and edge cases (like a worker walking into a restricted area) is the foundation of physical AI in construction.

There are several reasons 2026 is set to be a transformative year for physical AI in construction. AI-powered machinery is moving from the pilot stage to real deployments, unmanned job sites for tasks such as grading and trenching will be a reality, and there will be a greater focus on the collection of actionable real world data. This data will enable autonomous machines to operate more effectively and safely at scale, which will create even more high-quality data and lead to more deployments. It’s essential to establish this data feedback loop as quickly as possible—the leaders in physical AI will be the ones that build the strongest real-world data foundation, and the race is already on to do so.

The lack of data is one of the main limitations for physical AI, and this is particularly true in the construction industry. Construction is one of the most data-scarce industries, and it wouldn’t be economically practical for firms to try building the massive datasets that fuel other forms of physical AI (such as autonomous driving). This is why the deployment of physical AI in construction will require more efficient forms of data collection and analysis.

The next steps for physical AI in construction

A hallmark of the most advanced AI systems today is that they require massive amounts of compute power to stay on the cutting edge. McKinsey projects that there will be $6.7 trillion in global data center investments by 2030, and major companies like Google and Meta are making massive capital investments in GPUs and other types of AI infrastructure. Physical AI doesn’t require such a staggering level of compute, but it does rely on increasingly diverse and deep forms of data. However, there are innovative tools firms can use to leverage data more efficiently and increase the pace of real-world deployments.

For example, neuro-symbolic AI combines the power of neural networks with the structured and rules-based reasoning of symbolic systems. By enforcing hard rules and constraints, symbolic modules enable neural networks to learn from smaller datasets; ensure that AI-powered equipment is governed by rigid safety rules, operating limits, and regulatory standards; and provide visibility that other forms of AI lack. While neural networks are powerful tools for data analysis, they’re pattern recognition machines that don’t have a true understanding of physical reality. Neuro-symbolic AI combines the analytical power of neural networks with the real-world logic of symbolic reasoning.

Perhaps the most important element of neuro-symbolic AI is its interpretability. Instead of “black box” algorithms that can’t be investigated or understood by human analysts, neuro-symbolic AI provides transparency—its decision-making is intelligible, which is critical for building trust with regulators and operators. Once this trust is established, it will be easier for firms to deploy autonomous systems at scale. Tech providers must also be capable of showing firms how physical AI can serve their immediate needs, such as improving safety monitoring, enabling the remote operation of equipment, and providing predictive maintenance tools. By forging relationships with firms today by offering a clear value proposition—improving safety and efficiency through digitization—it will be possible to gather the proprietary data that will serve as the foundation for the next generation of autonomous models.

At a time when the construction industry faces a significant labor shortage and demand for advanced projects is rising, it’s no wonder that the growth of AI in construction is expected to surge over the next five years. By building strong relationships and establishing a firm data foundation in 2026, tech providers and construction firms will be capable of deploying physical AI at scale over the next several years.