Robotics 4.0: Transforming Manufacturing with Smart Automation

02 October 2024 | Market Trend

How Robotics 4.0 is Shaping the Future of Smart Factories

The integration of robotics with Industry 4.0 technologies is marking the next phase of industrial transformation, often referred to as Robotics 4.0. By merging robotics with AI, IoT, and cloud computing, industries are moving toward fully automated and intelligent manufacturing systems. This shift promises greater efficiency, flexibility, and productivity, helping manufacturers meet the demands of modern markets.

Image Source | Public Domain

The fusion of robotics with Industry 4.0 principles has heralded a new age in manufacturing—often referred to as Robotics 4.0. This integration of advanced robotics, artificial intelligence (AI), the Internet of Things (IoT), and cloud computing is pushing industries towards smart manufacturing. The goal is to create hyper-efficient, fully autonomous factories that enhance productivity, reduce waste, and allow for rapid customization.

Growing Innovation in Robotics 4.0

At the forefront of Robotics 4.0 is the development of collaborative robots (cobots) and AI-powered automation systems. Companies are using data analytics and sensor-driven automation to monitor and adjust factory processes in real time. Smart robots now feature greater decision-making autonomy, flexibility in task execution, and real-time adaptability. Below are examples of companies leading innovation in Robotics 4.0:

Key Company Projects in Robotics 4.0:

-

ABB Robotics

- Project: Smart Factories

ABB, a pioneer in industrial automation, has been focusing on transforming traditional factories into "smart factories" by integrating robots with AI and IoT. ABB’s YuMi robot is designed for precise, collaborative assembly work. Through cloud integration and machine learning, ABB’s robots can continuously optimize production processes and predict maintenance needs, reducing downtime.

- Case Study: ABB implemented its robotics solutions in BMW’s Leipzig factory to automate the complex task of assembling electric vehicle components. The result was a significant increase in assembly line efficiency and production accuracy.

-

Fanuc Corporation

- Project: Zero Downtime with AI-Based Predictive Maintenance

Fanuc has developed FIELD (Fanuc Intelligent Edge Link and Drive), a platform that uses AI to monitor the health of robots in real-time. Through predictive analytics, FIELD can anticipate failures, schedule maintenance, and even autonomously order parts before breakdowns occur. This system is already deployed in automotive manufacturing and has helped reduce operational costs.

- Example: Fanuc collaborated with General Motors to implement FIELD in its assembly plants, leading to a 20% reduction in unexpected downtime.

-

KUKA AG

- Project: Human-Robot Collaboration

KUKA is known for developing LBR iiwa, a lightweight, highly sensitive robot designed to work safely alongside humans. Its applications range from precise assembly in electronics manufacturing to collaborative work in healthcare and logistics. This robot leverages real-time data from sensors to respond instantly to its environment, enhancing productivity without compromising safety.

- Implementation: KUKA has partnered with Siemens to integrate iiwa robots in the production of hearing aids, enabling a seamless collaboration between humans and robots in delicate assembly tasks.

-

Yaskawa Electric Corporation

- Project: Robotics in Warehousing

Yaskawa has been at the forefront of using robotics for logistics and warehousing. Their Motoman series robots, equipped with machine learning and IoT sensors, are designed to handle tasks such as picking, packing, and sorting autonomously. With the integration of AI, these robots can quickly adapt to different packaging needs or inventory types.

- Example: Yaskawa worked with DHL to deploy Motoman robots in logistics centers, resulting in a 30% improvement in order fulfillment times.

Key Trends in Robotics 4.0

-

AI and Machine Learning Integration: The integration of AI with robotics enables machines to learn from data and improve performance autonomously. For instance, AI-driven robots are increasingly capable of complex decision-making tasks, which reduces human involvement in production processes.

-

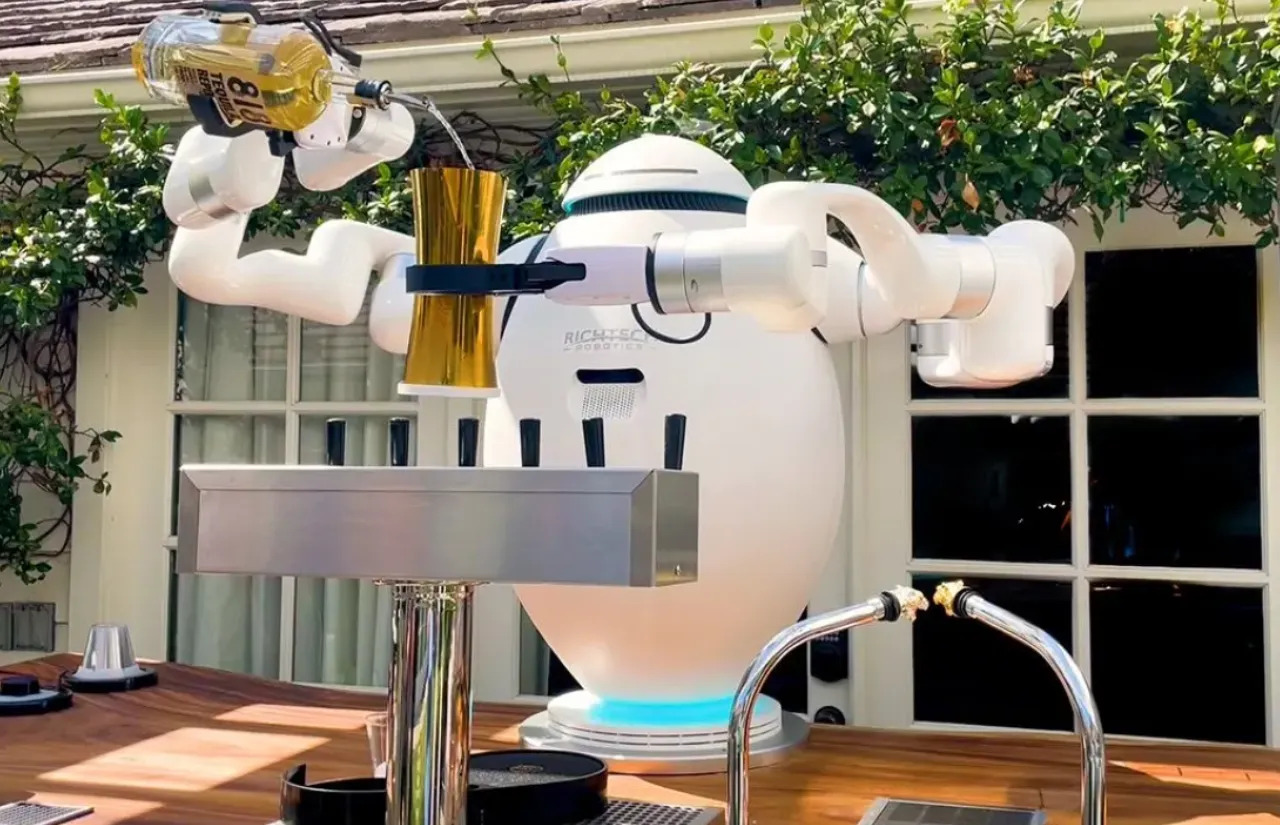

Collaborative Robots (Cobots): Cobots are designed to work side-by-side with human operators. Their sensitivity to surroundings and safety features allow them to assist in high-precision tasks, reducing the risk of accidents and improving workflow efficiency.

-

5G-Enabled Robotics: With the implementation of 5G, robotics systems can communicate faster and more reliably, enabling real-time adjustments and remote control in large, distributed manufacturing environments. This trend is expected to expand rapidly as 5G networks become more prevalent.

-

Robotics-as-a-Service (RaaS): Many companies now offer robots as a service, allowing businesses to lease robots instead of making hefty upfront investments. This model makes advanced automation accessible to smaller enterprises, driving adoption across industries.

Facts & Figures on Robotics 4.0

- Global Robotics Market Size: The market is forecast to grow from USD 89.68 billion in 2024 to USD 159.28 billion by 2029, with a CAGR of 12.17%.

- Cobots Market Growth: Collaborative robots are projected to reach USD 9.2 billion by 2028, driven by increasing applications in manufacturing, healthcare, and logistics.

- Smart Manufacturing Growth: The global smart manufacturing market is expected to reach USD 384.81 billion by 2028, growing at a CAGR of 10.3%.

Recent Advances in Robotics 4.0

-

Autonomous Mobile Robots (AMRs): Companies like Amazon and Fetch Robotics are using AMRs in warehouses to transport goods without the need for predefined paths, dramatically improving logistics and reducing operational bottlenecks.

-

Digital Twins in Manufacturing: Firms like Siemens are using digital twin technology to create virtual replicas of machines and production lines. This allows for testing and optimizing manufacturing processes digitally before making changes in the physical environment.

-

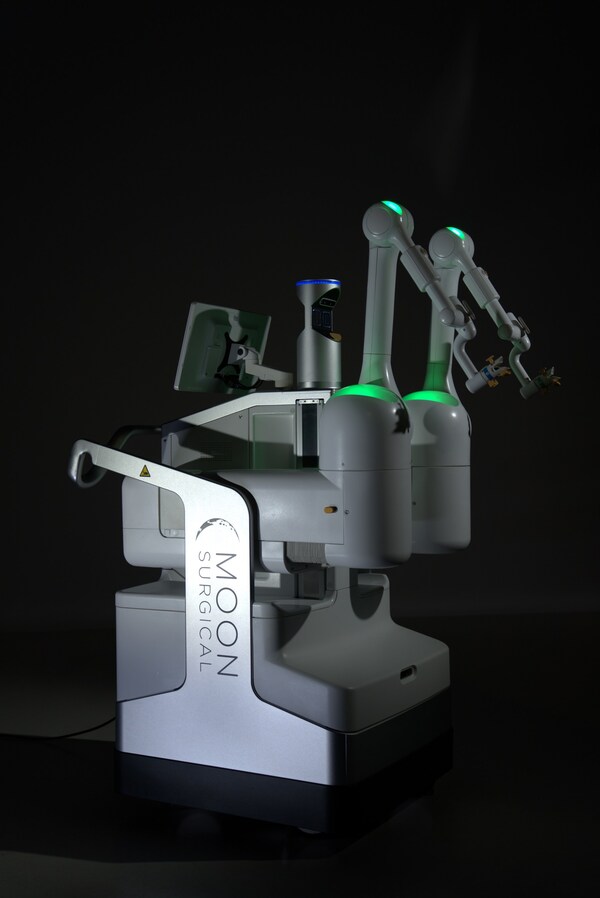

Robotics in Healthcare: Robotics 4.0 has seen significant advancements in healthcare, with companies like Intuitive Surgical deploying robots for minimally invasive surgeries. The company's da Vinci Surgical System is a market leader in robotic-assisted surgery, offering surgeons improved precision and control.

Industry Opinions on Robotics 4.0

Industry experts see Robotics 4.0 as a transformative force across multiple sectors. ABB’s CEO, Björn Rosengren, stated, "The shift to smart manufacturing is inevitable, and those who adopt Robotics 4.0 early will not only cut costs but also gain significant competitive advantages." Fanuc also emphasizes the role of AI and machine learning in driving future advancements, particularly in predictive maintenance and reducing operational risks.

Conclusion

Robotics 4.0 and smart manufacturing are redefining the future of production, with companies like ABB, Fanuc, KUKA, and Yaskawa at the forefront of innovation. As AI, IoT, and 5G continue to evolve, we can expect even greater levels of automation, customization, and efficiency in factories worldwide. The robotics revolution will not only reshape industries but also create new opportunities for collaboration between humans and machines.

Future Outlook

As Robotics 4.0 continues to mature, experts predict that by 2030, more than 50% of industrial tasks could be automated. Companies that invest early in smart manufacturing technologies will have a significant advantage in an increasingly competitive global market.