SEKISUI CHEMICAL Introduces PFAS-Free Pipe Material in Asia for Ultrapure Semiconductor Applications

In response to tightening PFAS regulations and environmental needs, SEKISUI's new olefin resin technology offers a sustainable alternative to fluorocarbon resins—reducing CO₂ emissions by 80% and aiming for market launch by FY2026.

SEKISUI CHEMICAL CO., LTD. announced that, in response to the global trend of tighter regulations regarding perfluoroalkyl and polyfluoroalkyl substances (PFAS) and growing demand for reducing environmental impact, the Urban Infrastructure & Environmental Products Company (President: Yoshiyuki Hirai) had been developing a new technology for PFAS-free pipe materials for ultrapure process applications in the manufacturing of advanced semiconductors. As a certain level of progress has been established in the development of this technology, SEKISUI CHEMICAL will start to formally propose it to customers.

1. Background

In the semiconductor and flat panel display (FPD) industries*, the ultrapure water being used needs to be supplied without lowering its water quality. The types of pipe materials for this purpose include those that use resin materials—hard polyvinyl chloride (PVC), polypropylene (PP), and fluorocarbon resins (polyvinylidene fluoride or PVDF, polytetrafluoroethylene or PTFE, and perfluoroalkoxy or PFA)—as well as those that use metallic materials in the form of metal pipes with special surface treatment. Today’s advanced semiconductor industry, with the progress of ultra-miniaturization, requires pipe materials that can suppress the elution of inorganic and organic matter as far as possible.

* The flat panel display (FPD) industry refers collectively to all industries related to the manufacture of flat panel displays, including liquid crystal displays, organic EL displays, and LED displays.

2. PFAS and Its Regulation

PFAS refers to perfluoroalkyl and polyfluoroalkyl substances, which are difficult to break down in nature and may affect the human body or ecosystems. Among PFAS, the manufacture, import, and such of perfluorooctanoic acid (PFOA) and perfluorooctanesulfonate (PFOS) are already prohibited. As of now, PVDF, PTFE, and other materials used in fluorocarbon resin pipes and fittings for ultrapure process applications are not within the scope of regulation in Japan. However, in Europe and the United States, studies are being conducted to comprehensively subject PFAS to regulation. Together with other initiatives, there is a global trend of tighter regulations regarding PFAS.

3. Chronology of Development

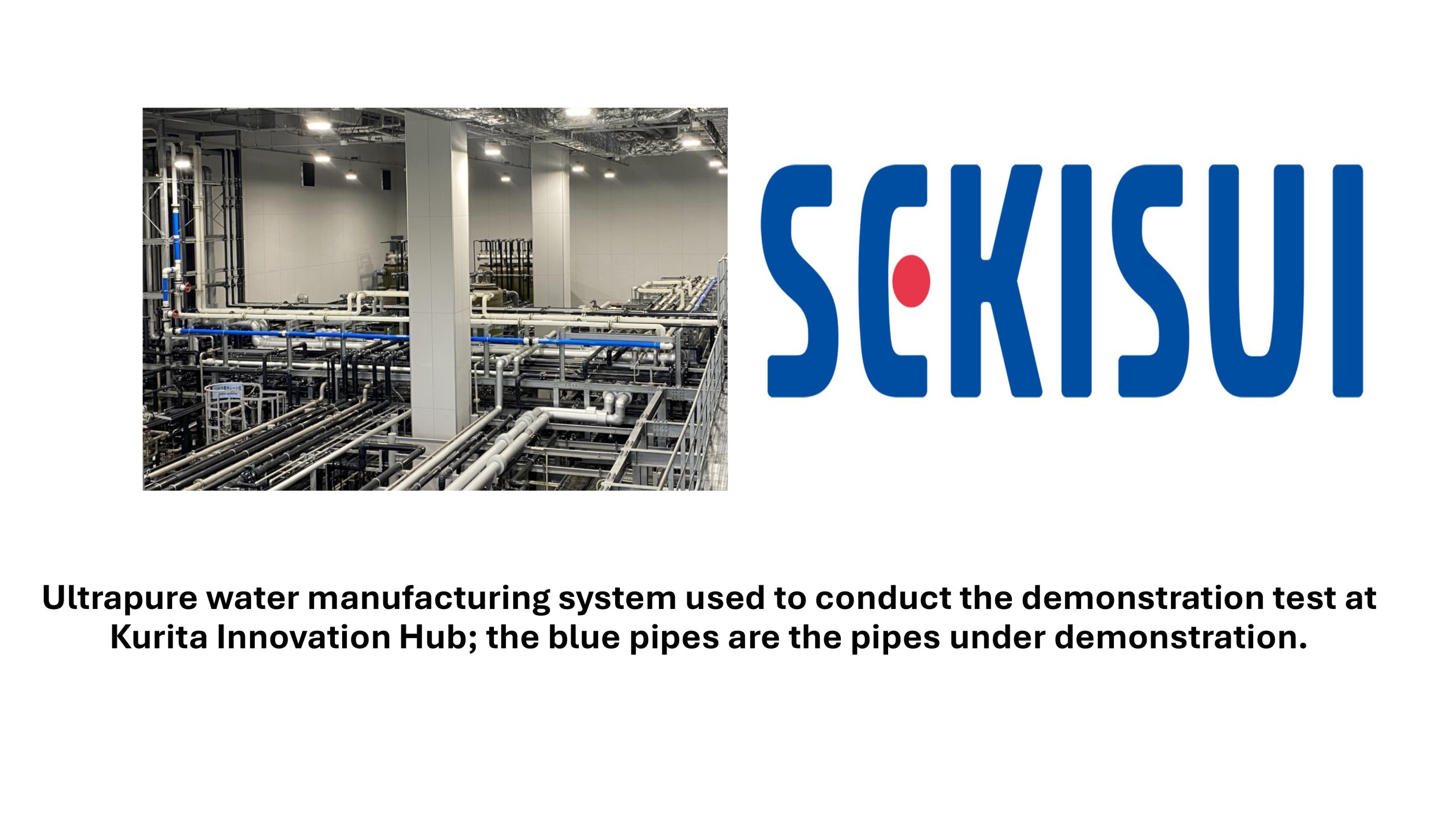

As a pioneer of plastic piping materials, SEKISUI CHEMICAL launched “Eslon Clean Pipe”—a hard PVC pipe material for transporting ultrapure water—in 1984. Since then, supported by an impressive track record, the product has been used in a wide range of applications. This time, a special olefin resin pipe material has been developed as a new low-elution material replacing fluorocarbon resins from the perspective of PFAS. In November 2022, a demonstration using an actual ultrapure water manufacturing system was started jointly with Kurita Water Industries Ltd. Compared to existing fluorocarbon resin pipe materials, this special olefin resin pipe material can reduce CO2 emissions during manufacturing by approximately 80%. Furthermore, in response to the global trend of PFAS regulation, SEKISUI CHEMICAL started working on developing PFAS-free pipes and fittings for ultrapure process applications.

4. Future Prospects

With the establishment of this PFAS-free technology, SEKISUI CHEMICAL will start to formally propose it to customers and will aim for market launch within fiscal 2026. The company will also undertake development toward the early realization of creating valves, gaskets, and other pipe materials that are totally free from PFAS in the area of ultrapure process applications.

SEKISUI CHEMICAL is accelerating the creation and market expansion of products—such as clean pipes—with high contribution to solving issues in the natural and social environments. For the realization of a sustainable society as well as sustainable growth as a company, the Products to Enhance Sustainability System is being promoted Group-wide to achieve ESG management at a higher level.

SEKISUI CHEMICAL will seek to realize a sustainable society by 2030 through creating products that can contribute to solving issues in the natural and social environments when being manufactured as well as when customers use them.