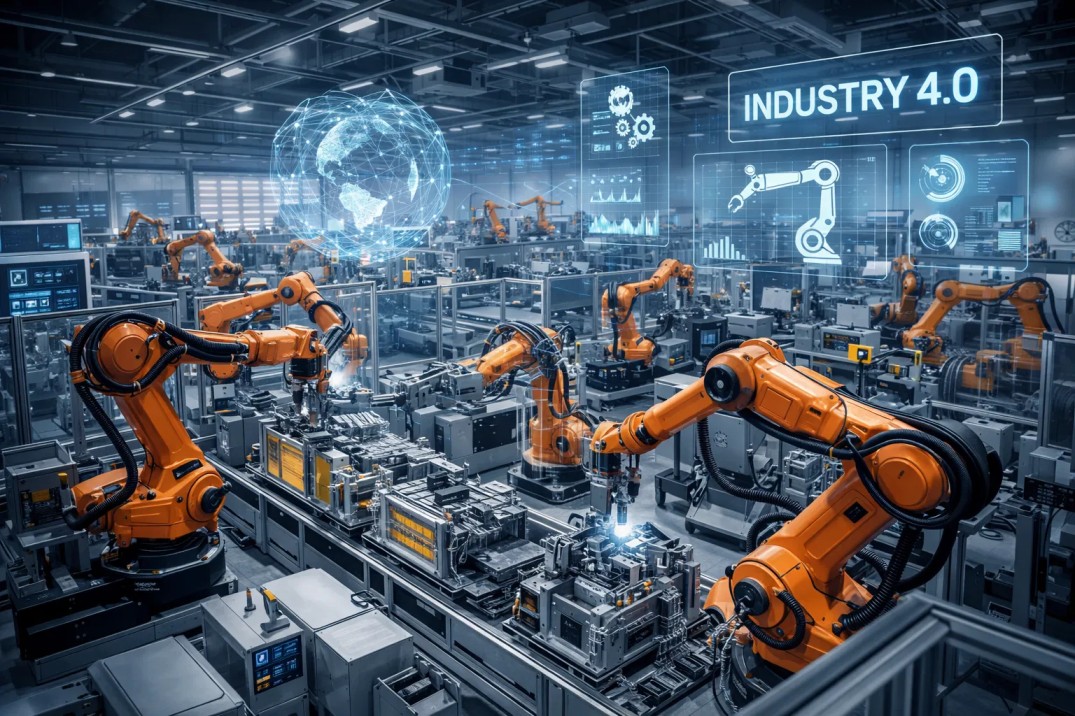

Symbotic Launches Next-Gen Ultra-Dense Storage System to Boost Warehouse Automation Efficiency

With up to 40% footprint reduction, faster bot trips, and rapid deployment via pre-assembled components, Symbotic’s latest innovation transforms warehouse speed, scalability, and ROI.

Image Courtesy: Public Domain

- Innovative Design Provides Ultra-High Density for Increased Storage Capacity and/or Reduced Footprint

- Denser Storage Enables Shorter and Faster Bot Trips per Case Delivery

- Pre-Assembled Components Deliver Faster Implementation in Customer Sites, Accelerating Time to Value

Symbotic Inc. a leader in A.I.-enabled robotics technology for the supply chain, announced the commercial availability of its innovative next-generation storage technology. Designed to significantly enhance the performance of its industry-leading warehouse automation system, the new structure is engineered to deliver substantially increased storage capacity for products, faster deployment and case handling, enhanced fire suppression, and improved seismic adaptability. To see Symbotic’s next-generation storage, click here.

Symbotic has coupled the exceptional, industry-leading density offered by its current system with a breakthrough innovation that can reduce customers’ storage footprint by up to 40% of its original size. This will enable customers to fit considerably more products into a fixed space, or attain a target storage volume in a smaller footprint. Case handling speed will also be enhanced: the increased storage density will mean shorter – and faster – bot trips per case delivery.

Additionally, Symbotic’s next-generation storage is engineered for rapid deployment. The innovative structure features pre-assembled, precision-manufactured sub-components that will reduce the number of on-site assembly parts by over 90% and lower system implementation time at customer sites.

Further key benefits of Symbotic’s next-generation storage design include:

- Modular shelf configurations that accommodate a broader range of products and boost storage density

- Pre-engineered safety features and integrated fire suppression

- Structural strengthening options providing flexibility to meet seismic requirements

- Reduced site readiness costs through a unique leveling system that minimizes floor preparation

The new storage and buffering structure can be implemented as a retrofit to existing facilities or in new greenfield buildings, as part of the end-to-end Symbotic System.

“Customers are increasingly looking for flexible, ultra-high density warehouse automation to ensure the reliable flow of goods to consumers, and we’re seeing immediate traction with this new technology,” said Rick Cohen, Chairman and CEO of Symbotic. “Our next-generation storage structure represents a major leap forward in our mission to help customers improve efficiency, speed and resilience – all while accelerating return on investment.”