Corvus Robotics Launches Autonomous Cold Chain Inventory Drones for Freezer Warehouses

Corvus One™ for Cold Chain delivers continuous, human-free inventory visibility in sub-zero environments

Image Courtesy: Public Domain

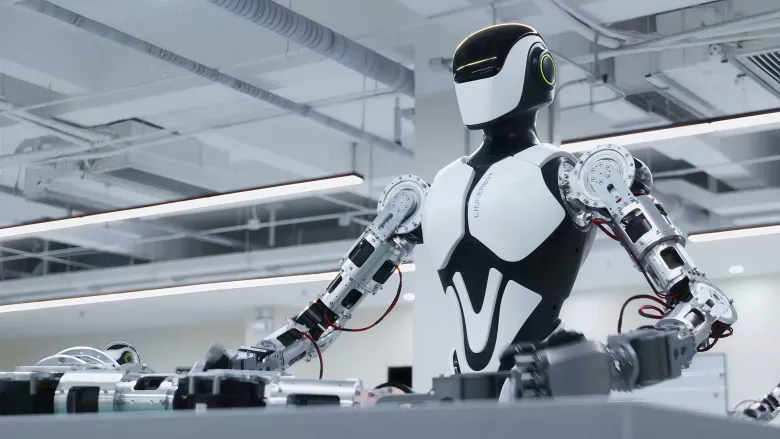

Corvus Robotics, a leader in deploying physical AI robotic systems for logistics and warehousing operations, announced Corvus One™ for Cold Chain, an autonomous inventory management system engineered to operate continuously in freezer environments ranging from minus-20 degrees Fahrenheit to ambient temperatures. Designed to withstand extreme cold, airflow, frost, and condensation, the system delivers frequent, accurate inventory cycle counts without human intervention, enabling operators to maintain real-time visibility while keeping labor and equipment out of harsh freezer conditions.

Watch Corvus One for Cold Chain drones operating in freezers

“Operating autonomous aerial systems continuously in freezer environments is an engineering challenge most robotics platforms were never designed to handle,” said Jackie Wu, Chief Executive Officer, at Corvus Robotics. “Corvus One for Cold Chain required re-architecting thermal management, sensing, flight stability, and onboard perception so the system could maintain autonomy and accuracy despite frost, glare, airflow, and extreme temperature swings. The result is a system that performs reliably in environments that have historically defeated automation.”

A leading national grocer, Kroger, is already using Corvus One for Cold Chain in live freezer operations, where the system is delivering consistent inventory visibility and reducing reliance on manual cycle counts in sub-zero environments.

Corvus One for Cold Chain maintains full flight and scanning performance in sub-zero conditions using industrial-grade barcode scanners that provide precise control over focus and exposure. The system adapts to each environment to maintain barcode readability despite frost or glare, and automatically stabilizes flight to compensate for strong airflow, allowing freezer blowers and door activity to operate normally.

Corvus One for Cold Chain provides the following benefits:

High-Frequency Inventory Audits for Freezer SKU Velocity

Short shelf lives, strict FIFO requirements, and expanding SKU counts make frozen inventory especially difficult to manage. Corvus One performs frequent, fully autonomous cycle counts to keep inventory data continuously current. Operators gain precise visibility into pallet positions and dwell time, reducing write-offs, improving replenishment accuracy, and enabling tighter space optimization.

Reduced Labor Exposure and Improved Worker Safety

Freezer operations drive higher labor costs due to specialized gear, limited exposure windows, and shorter shifts. Corvus One for Cold Chain operates autonomously in temperatures as low as -20°F, eliminating the need for associates to enter freezer aisles for routine inventory counts and reducing both safety risk and labor overhead.

Reliable Barcode Capture in Sub-Zero Conditions

Ice buildup, condensation, glare, and damaged labels degrade the performance of conventional scanning systems. Corvus One uses industrial-grade barcode scanners with adaptive focus and exposure control, combined with stabilized flight, to consistently read frosted or low-contrast labels from multiple angles in challenging freezer environments.

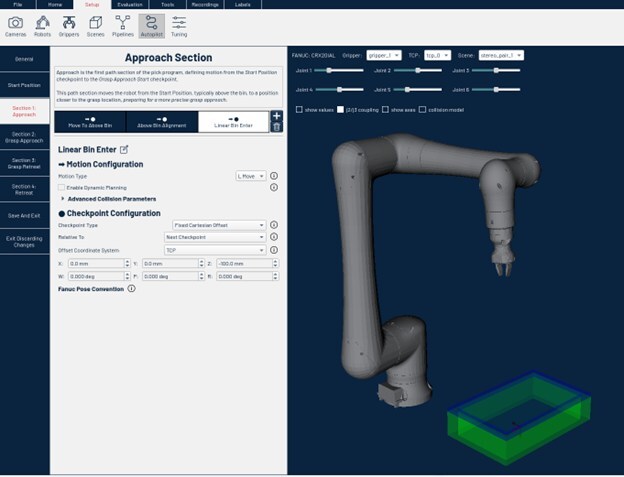

Autonomous Operation Without Workflow Disruption

Corvus One for Cold Chain operates without Wi-Fi, localization markers, lighting modifications, or special barcodes. The system flies autonomously during active shifts, adapts to airflow from blowers and door activity, and maintains continuous uptime through automated battery and device health management under Corvus Robotics’ Robots-as-a-Service model.