Saronic Explores Physical AI Welding Robotics to Accelerate Autonomous Shipbuilding in Louisiana

Collaboration with Saronic and Path Robotics integrates advanced AI-driven welding systems at the Franklin shipyard, strengthening American maritime manufacturing capacity.

Image Courtesy: Public Domain

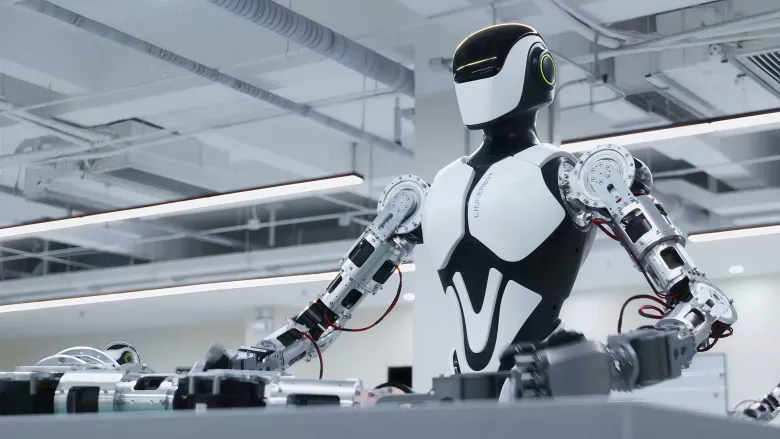

Saronic is on a mission to revitalize American shipbuilding, creating new domestic capacity through the expansion of its shipyard in Louisiana and the development of Port Alpha. To accelerate the delivery of autonomous maritime vessels, the company today announced plans to explore the integration of physical AI for welding robotics across its shipyard operations. These advanced manufacturing technologies are designed to increase safety, improve efficiency, and increase throughput, while bolstering production consistency and quality. This complements Saronic’s significant, ongoing investments in shipyard infrastructure, workforce expansion, and skilled hiring across its Louisiana operations.

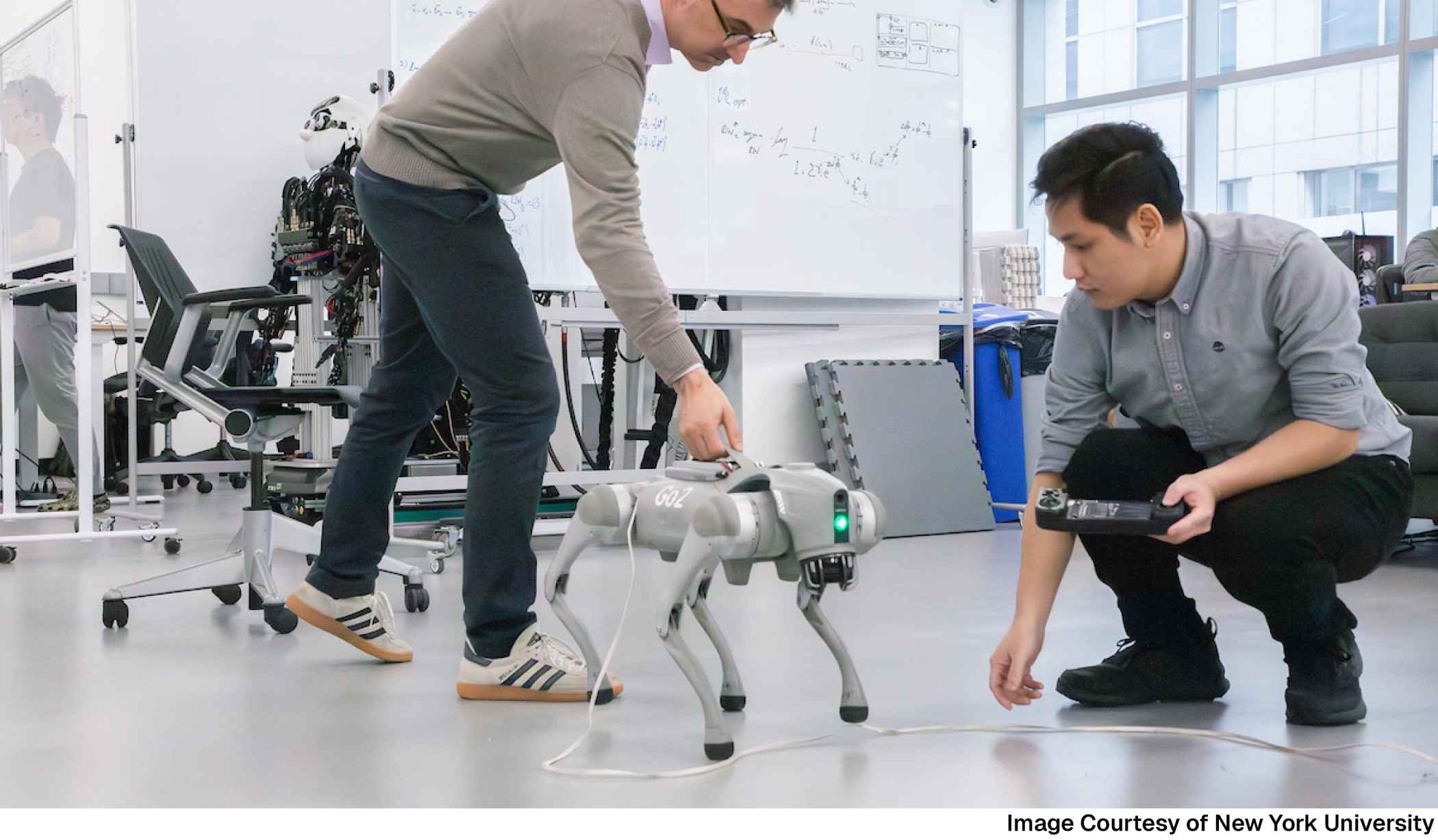

As part of this effort, Saronic has launched a collaboration with Path Robotics to integrate physical AI for welding robotics into its Franklin, Louisiana shipyard. The initial rollout will focus on intelligent welding cells, combining Path’s proven welding models with Saronic’s world-class welding team to deliver significant advancements in production efficiency, quality and repeatability.

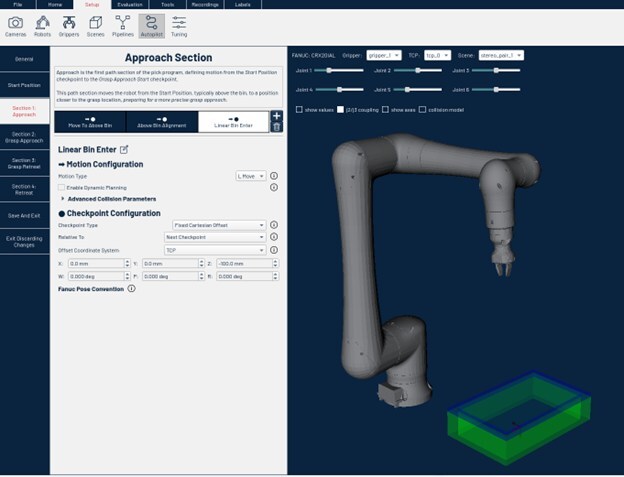

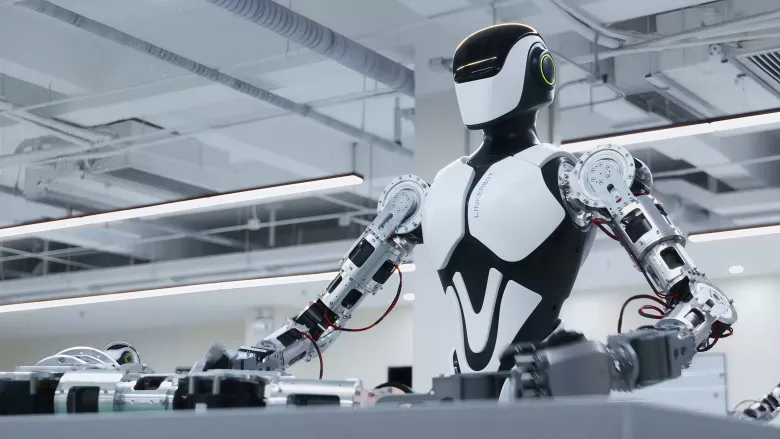

Just as Saronic is pioneering the frontier of physical AI in the maritime domain, Path is pioneering the frontier of physical AI in manufacturing. Path’s welding models combine computer vision, machine learning, AI, and robotics to automate complex welding tasks in heavy manufacturing environments. To date, Path has trained its physical AI on tens of millions of welded inches.

The initiative will integrate Path’s physical AI systems directly into Saronic’s shipyard workflow. By pairing physical AI that can see, reason, and adapt in real time with its linear production methodologies, Saronic is defining the next-generation approach to high-volume shipbuilding.

“Restoring America’s maritime industrial capacity requires rethinking how shipyards are designed and operated from the ground up,” said John Morgan, Saronic’s Head of Manufacturing. “At Saronic, we are exploring how physical AI and automation can help advance shipbuilding operations, just as our autonomous systems are transforming maritime operations at sea. This collaboration allows us to learn how Path's technology can be applied within our shipbuilding environments and scaled to support a more modern, resilient production model.”

“We are proud to partner with Saronic, whose leadership in the maritime domain is helping advance a new era for U.S. shipbuilding,” said Andy Lonsberry, CEO and co-founder, Path Robotics. “America’s shipyards are under immense pressure to deliver more capacity, faster, driving an increased demand for skilled welders. Physical AI gives them a new path forward - one that brings together skilled shipbuilders and advanced technologies. By embedding real-time intelligence directly into robotic welding systems, we’re enabling shipbuilders to automate complex, variable welding tasks, unlocking the next generation of manufacturing on the shipyard floor and empowering American craftsmen.”

Software-Led Shipbuilding

From its inception, Saronic has taken a software-led, AI-first approach to autonomous ship design, enabling high performance while reducing complexity and inefficiency. That same systems-driven philosophy extends to Saronic’s manufacturing approach, where software, data and intelligent automation drive how work is planned, executed and scaled. By testing, evaluating, and ultimately scaling the deployment of these capabilities at its Louisiana shipyard, Saronic is defining how next-generation manufacturing technologies can further accelerate the production of autonomous ships at speed and scale.

The collaboration with Path Robotics is part of Saronic’s broader effort to deploy advanced manufacturing capabilities and techniques that accelerate shipyard operations, alongside continued investment in the growth of its skilled shipbuilding workforce. Complementary initiatives include evaluating additional automation capabilities to drive process improvements, as well as new software tools to streamline shipyard workflows. Together, these efforts augment Saronic’s skilled shipbuilding workforce by pairing experienced craftspeople with software-driven capabilities that enable consistent, high-quality production. As the shipyard expands, Saronic will continue to evaluate additional advanced manufacturing technologies to further enhance production efficiency and reliability.

Field-tested manufacturing and robotics integration from the Franklin shipyard will serve as the foundation for the design and build-out of Port Alpha, Saronic’s next-generation shipyard. Port Alpha will incorporate automation, advanced manufacturing, and software-defined systems from the outset. By designing the shipyard around robotics-enabled production, Saronic is establishing a scalable shipbuilding model that enables sustained production capacity for the future of American shipbuilding.