Comau Introduces MyMR Mobile Robot Lineup to Transform Intralogistics

Launching at Automatica 2025, the new MyMR AMRs deliver flexible, scalable, and infrastructure-free automation with intelligent navigation and modular design—accelerating the future of agile, human-centric material handling across industries.

Image Courtesy: Public Domain

- Comau is launching three new Autonomous Mobile Robots – with payloads ranging from 300kg to 1.5 tons, for enhanced intralogistics and warehouse automation

- Flexible, scalable, and infrastructure-free, MyMR robots offer hybrid navigation (AMR/AGV) and intelligent fleet management, enhancing productivity without requiring facility modifications

- Engineered for next-generation manufacturing and material handling across diversified industries, MyMR supports the evolution toward agile production flows and reconfigurable factories

- The solution combines Comau’s robotics expertise and system integration capabilities in a single turnkey offering that integrates seamlessly with existing systems

- By reducing deployment times, improving collaborative safety, and lowering handling costs, MyMR delivers measurable value and a fast return on investment

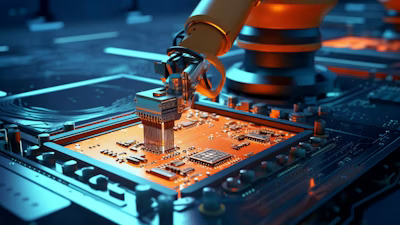

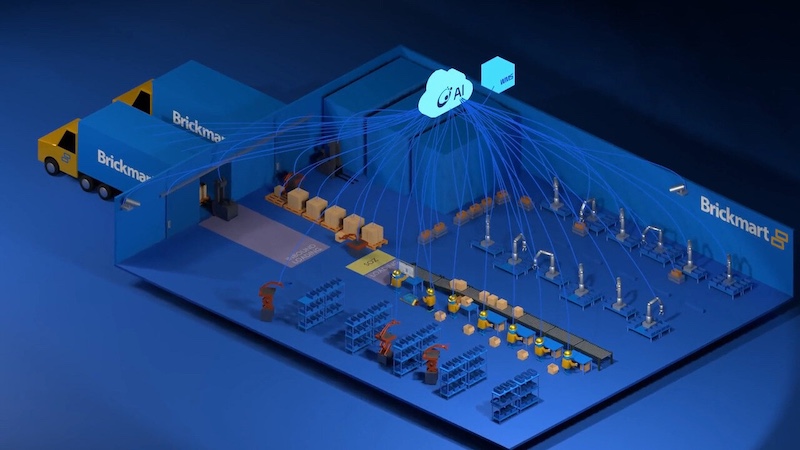

Comau, a global leader in advanced industrial automation, will launch its MyMR family of Autonomous Mobile Robots (AMRs) at Automatica 2025 (Munich, Germany, June 24-27), the leading international trade fair for automation and robotics. Engineered to meet the increasing demands of intralogistics across manufacturing, warehousing, logistics and highly automated environments, the MyMR platform addresses key challenges such as labor shortages, material handling inefficiencies, and safety concerns with a modular, scalable and fully autonomous solution.

Unlike traditional automation systems or manual handling processes, MyMR offers advanced features such as intelligent fleet management, real-time obstacle avoidance and seamless line integration. With three distinct models offering payload capabilities of 300 kg, 500kg and 1,500 kgs, Comau’s AMRs support a broad range of logistics tasks from production line supply to warehouse automation and kitting. The advanced navigation system allows them to dynamically adapt to layout changes, enhancing flexibility and operational uptime without requiring dedicated infrastructure or predetermined trajectories.

Designed to support diversified industries, MyMR reflects Comau’s vision of the mobile, digitally connected factory. The platform enables safe human-machine collaboration, empowering decentralized, agile production flows while ensuring that the AMRs and workers operate work side-by-side to optimize productivity and responsiveness.

In addition to the three AMR models that comprise the MyMR family, Comau offers standard attachments such as lifters, conveyors, shelving and other accessories to address a full range of warehouse automation and intralogistics needs. Furthermore, MyMR robots can be easily converted from an Autonomous Mobile Robot to an Automated Guided Vehicle thanks to their advanced software configuration. This enables additional flexibility and functionality as the customers’ needs change.

“The global debut of MyMR robot family at Automatica underscores our commitment to redefining intralogistics through intelligent, mobile automation,” said Nicole Clement, Chief Business Unit Leader - Advanced Automation Solutions of Comau. “AMRs and AGVs are expected to become one of the fastest-growing segments within industrial automation, reaching a CAGR of 31% through 2027 according to our estimates. By adding this essential automation enabler within our vast product portfolio, Comau now has a complete, integrated ecosystem to help our customers enhance flexibility, safety, and efficiency across the intralogistics value chain.”