Cobots Surge in 2025: Collaborative Robotics Redefining Industrial and Service Automation

18 July 2025 | Market Trend

With AI-powered adaptability, safety-first design, and expanding use cases across sectors, collaborative robots are leading the next frontier of human-machine synergy.

Image Courtesy: Public Domain | By Robotics Business News | June 2025

As industries rethink the future of labor and automation, collaborative robots—once confined to repetitive factory tasks—are stepping into the spotlight as agile, AI-powered partners in nearly every sector of the economy.

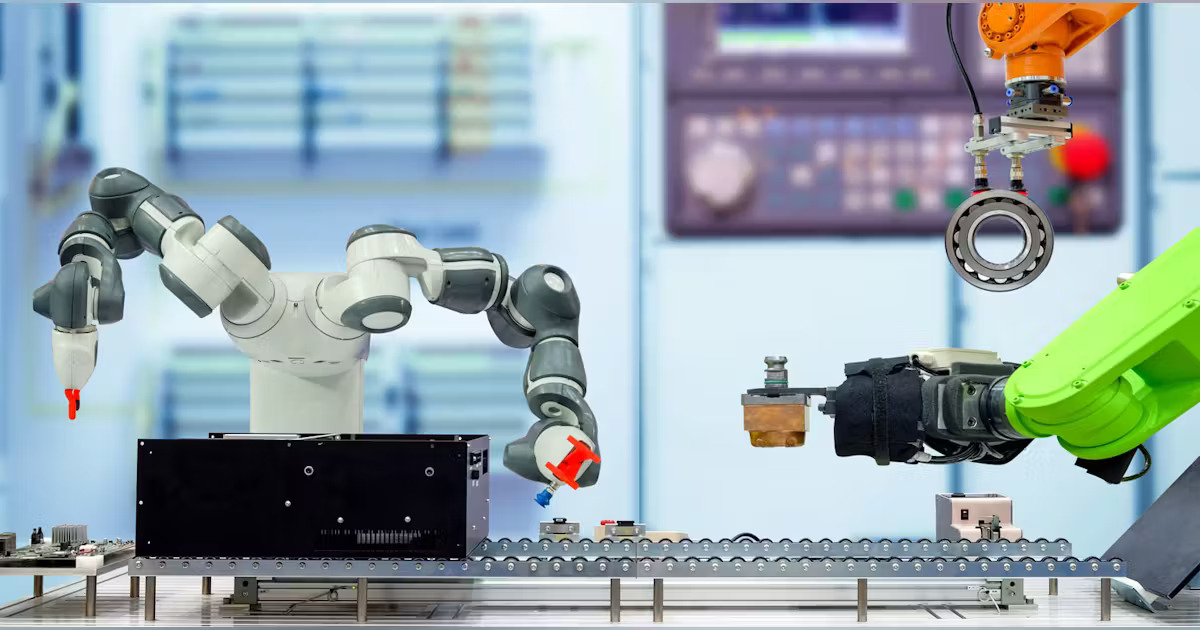

Once viewed as limited robotic arms working safely beside humans, collaborative robots (cobots) have undergone a transformative evolution. In 2025, they are intelligent, mobile, and often multilingual—designed not just to support labor but to amplify it. This year marks a pivotal moment in cobotics, where the focus shifts from automation to collaboration, with cobots now active in healthcare, hospitality, logistics, agriculture, and even education.

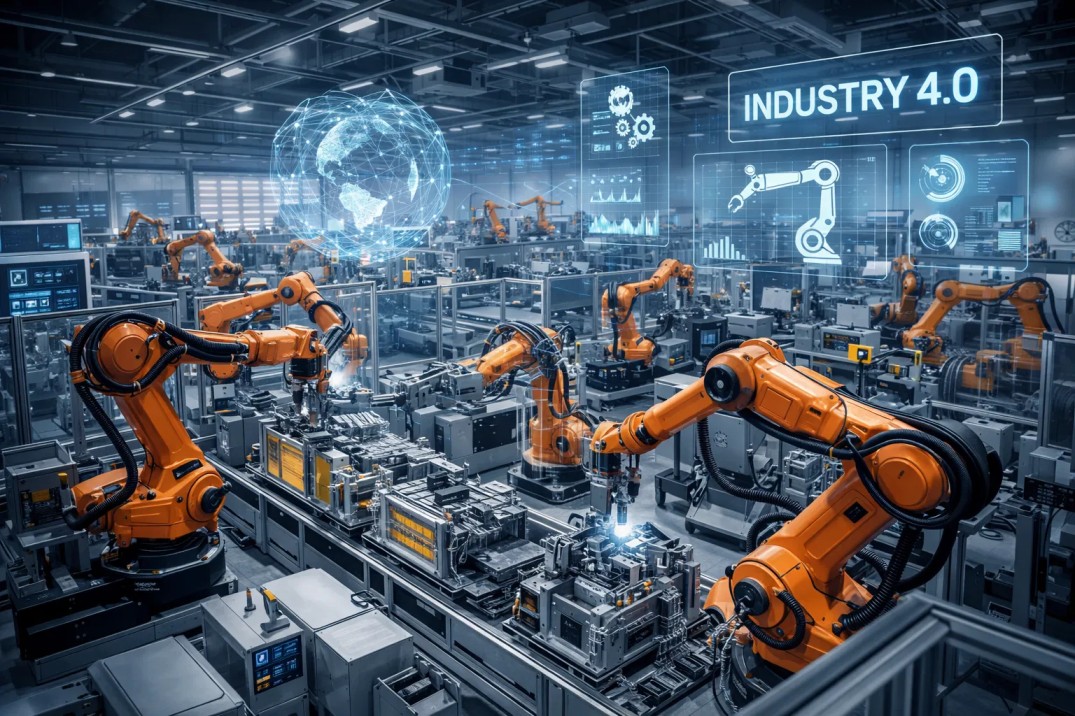

Market Momentum and Global Adoption

The global cobot market is expected to reach $3.6 billion by the end of 2025, according to IDC, with double-digit growth driven by demand for flexible, scalable automation. Regions such as North America, Europe, and East Asia are leading the charge, but new investments in India, Southeast Asia, and South America are signaling a truly global shift.

AI-Powered Intelligence: Beyond the Arm

Today’s cobots are equipped with multimodal sensors, edge-AI processing, and natural language understanding. These capabilities are enabling cobots to:

-

Understand verbal commands from non-engineering staff

-

Detect and respond to human motion and intent in real time

-

Continuously learn and adapt using cloud-based training data

-

Perform fine motor tasks previously exclusive to human dexterity

Companies like Techman Robot, ABB, and Universal Robots have integrated vision-guided manipulation and contextual AI agents into their latest platforms, enabling a single cobot to handle multiple tasks across different departments without needing reprogramming.

Cobots at Work: Sector Spotlights

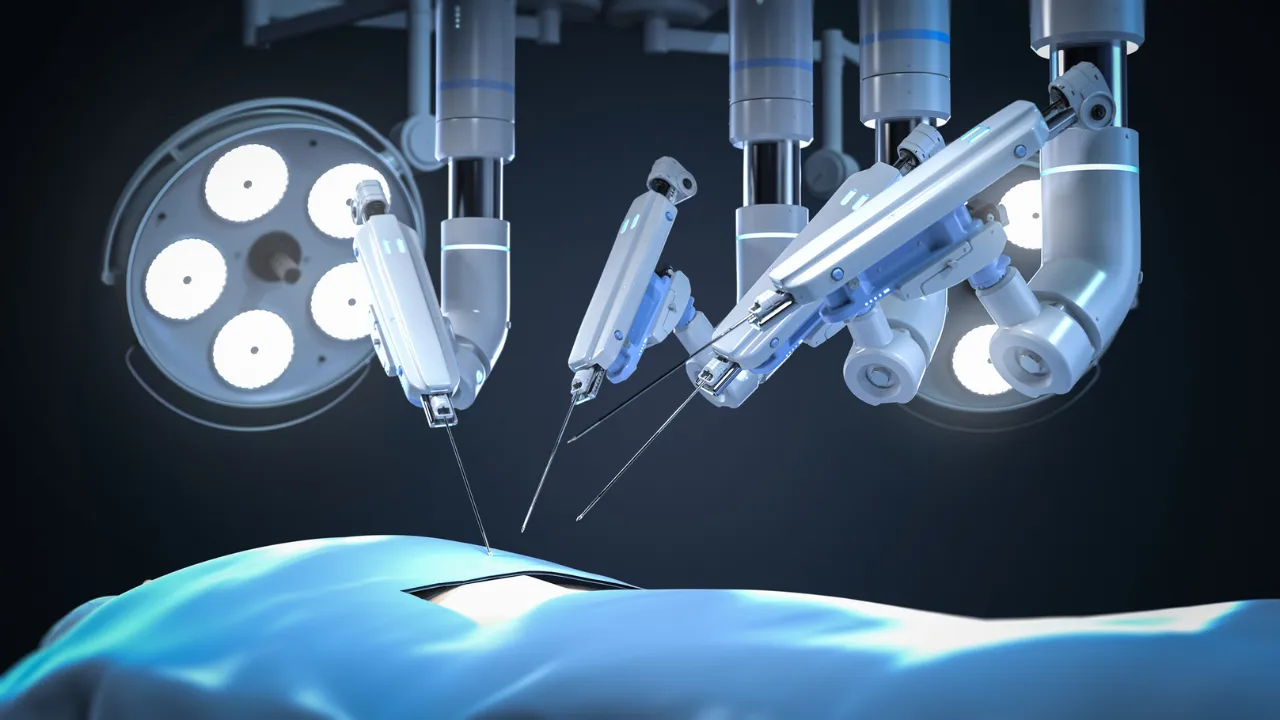

Healthcare

Hospitals are now using cobots for patient transport, pharmacy automation, and even bedside support. The KairoCare Cobot, launched in April 2025, features a soft-touch arm and built-in emotion recognition to assist nurses in geriatric wards.

Construction & Maintenance

From drywall finishing to welding rebar, cobots are increasingly seen on job sites. BuildBot X5, an AI-cobot system piloted in Dubai and Austin, enables mixed-reality collaboration between onsite workers and remote engineers.

Hospitality

With labor shortages continuing across the hospitality industry, cobots like SerBot Neo are greeting guests, cleaning hotel rooms, and mixing drinks—all while syncing with IoT systems to manage inventory and guest preferences.

Logistics and Warehousing

Cobots integrated into fulfillment centers are helping solve the "last 50 feet" challenge. Instead of just moving boxes, they’re sorting, scanning, and preparing orders using dynamic AI models trained on SKU variations.

Human-Centered Design and Safety

The heart of collaborative robotics remains safety and trust. With updated ISO 10218 and ISO/TS 15066 compliance, cobots now feature:

-

Real-time force limitation and haptic feedback

-

Predictive motion planning to avoid collisions

-

Skin-based tactile sensors and emergency override systems

As machines grow more intelligent, ensuring ethical, safe, and user-friendly operation is paramount. Companies are investing in human factors design to ensure that cobots are not only effective but also empathetic in their interaction.

Looking Forward: The Cobot as Coworker

In the next two years, experts predict that cobots will take on more decision-support roles. Rather than simply executing instructions, cobots will become team members—offering suggestions, flagging inefficiencies, and collaborating in real time with both humans and other machines.

Final Thought

The cobot revolution isn’t just about robots working with humans—it’s about reshaping how we define work itself. As AI, robotics, and systems thinking converge, collaborative robotics is not replacing the workforce but reinventing it—one task, one team, and one touch at a time.