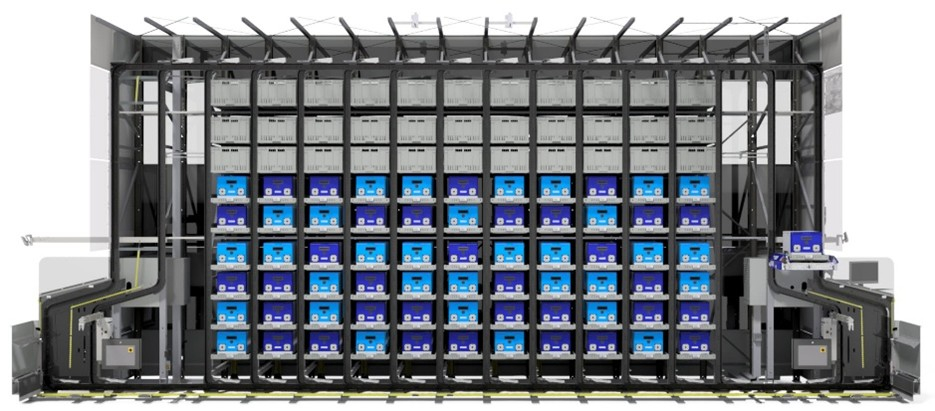

Berkshire Grey Launches Scoop™ Robotic Trailer Unloading System to Transform Dock Operations

New Scoop system delivers market-leading throughput, safer operations, and improved productivity in the most variable warehouse environments

Image Courtesy: Public Domain

Berkshire Grey, a global leader in AI-enabled robotic automation, today announced the launch of the Scoop™, a robotic trailer unloading system designed to deliver market leading throughput rates and improved productivity where variability is highest: inside the trailer.

Across parcel, retail, eCommerce, and 3PL distribution centers, the dock remains one of the most operationally difficult and physically demanding parts of the building. When inbound unloading becomes the constraint, the impact cascades downstream affecting the entire warehouse operation. The Scoop system safely reduces this volatility while improving overall unloading performance.

The company is currently completing customer-installed pilot programs for Scoop with production systems to be deployed in 2026.

A systems approach built for safety, productivity and load variability

Scoop’s dual mode picking and induction system enables seamless handling of unstructured loads and improves throughput rates. Unlike other robotic trailer unloading systems, Scoop is not limited to item-by-item handling or the need to operate under a narrow set of unloading conditions.

- Delivers high package handling rates: Increased throughput due to a bulk unloading approach that extracts a variety of load types simultaneously vs. item-by-item handling.

- Built for unstructured trailer loads: Seamlessly processes mixed parcel sizes, shapes, collapsed walls, floor-level piles, and soft-sided parcels (including polybags).

- Dual mode approach for continuous flow: Utilizes picking and induction features to orchestrate consistent inbound flow.

- Brownfield-ready integration: Designed to deploy into existing dock environments using available infrastructure.

- Safety-forward, controlled operation: Provides controlled access and predictable system behavior to support safe and efficient human interaction when required.

“Dock operations are where real-world variability and labor constraints collide, and that volatility can set the pace for an entire facility,” said Dave Paratore, Chief Executive Officer, Berkshire Grey. “With Scoop, we’re bringing production-grade, reliable automation to the trailer door - enabling the combination of measurable productivity gains and higher package handling rates. This embodies Berkshire Grey’s philosophy of “make it easier” for the customer to be successful.”

This introduction leverages more than a decade of expertise in picking and sortation automation for logistics, distribution and fulfillment operations and represents an initial entry into the Dock Automation Market with other expansions forthcoming.